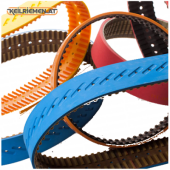

V-ribbed, toothed and flat belts

General information

In the product group of flat, V-ribbed and timing belts, there are power transmissions that are constructed differently than V-belts. The flat belt is the oldest drive belt, originally made of leather, now made of rubber and fabric. The advantage is that it rotates well even on a relatively smaller pulley, the disadvantage is that it moves on the pulley and can easily slip from it... It can transmit less torque than V-belts, but tolerates slipping well. V-ribbed belts combine the advantages of flat belts with the positive properties of V-belts. It's like tiny V-belts glued together... They can also be used on small diameter pulleys and transmit large forces. It is often found as a drive belt for machines and devices. Timing belts are a combination of V-belt drive and chain drive. The power is transmitted not only through friction, but also thanks to the transverse ribs on the belt, it nestles against the drive wheel, so that it can transmit almost the same driving forces as the V-belt drive with a smaller, significantly more compact design. Due to their greater flexibility, V-ribbed belts are used in applications with high back bending.

General information

In the product group of flat, V-ribbed and timing belts, there are power transmissions that are constructed differently than V-belts. The flat belt is the oldest drive belt, originally made of leather, now made of rubber and fabric. The advantage is that it rotates well even on a relatively smaller pulley, the disadvantage is that it moves on the pulley and can easily slip from it... It can transmit less torque than V-belts, but tolerates slipping well. V-ribbed belts combine the advantages of flat belts with the positive properties of V-belts. It's like tiny V-belts glued together... They can also be used on small diameter pulleys and transmit large forces. It is often found as a drive belt for machines and devices. Timing belts are a combination of V-belt drive and chain drive. The power is transmitted not only through friction, but also thanks to the transverse ribs on the belt, it nestles against the drive wheel, so that it can transmit almost the same driving forces as the V-belt drive with a smaller, significantly more compact design. Due to their greater flexibility, V-ribbed belts are used in applications with high back bending.

Double-sided ribbed belts are primarily used in the food industry. Double timing belts are toothed on both sides and can transmit the drive on both sides. We use them when we want to drive one wheel in one direction and the other wheel in another direction... They are most commonly used on lawn mowers and milling machines. Timing belts sold by the meter are mostly used for linear movements, but the polyurethane versions can be made endless by welding together so that they can also be used as drive belts. In the special timing belt group you will find the toothed versions of cable puller timing belts, film puller timing belts and mill belts for the mill industry.

Double-sided ribbed belts are primarily used in the food industry. Double timing belts are toothed on both sides and can transmit the drive on both sides. We use them when we want to drive one wheel in one direction and the other wheel in another direction... They are most commonly used on lawn mowers and milling machines. Timing belts sold by the meter are mostly used for linear movements, but the polyurethane versions can be made endless by welding together so that they can also be used as drive belts. In the special timing belt group you will find the toothed versions of cable puller timing belts, film puller timing belts and mill belts for the mill industry.

News

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next