Double tooth timing belts

General information

Double-toothed timing belts are flat belt products with protrusions (teeth) at regular intervals on both sides. Through their mechanical grip, these teeth transfer power from the drive wheel to the driven wheel in a manner similar to a chain drive. For the use of toothed belts, a special pulley, so-called a splined wheel is required. Each timing belt type has its own toothed wheel. Double-jointed toothed belts run on the same pulley as their toothed pair on one side, but so-called they are suitable for serpentine drive, i.e. for driving rib wheels rotating in opposite directions.

General information

Double-toothed timing belts are flat belt products with protrusions (teeth) at regular intervals on both sides. Through their mechanical grip, these teeth transfer power from the drive wheel to the driven wheel in a manner similar to a chain drive. For the use of toothed belts, a special pulley, so-called a splined wheel is required. Each timing belt type has its own toothed wheel. Double-jointed toothed belts run on the same pulley as their toothed pair on one side, but so-called they are suitable for serpentine drive, i.e. for driving rib wheels rotating in opposite directions.

Double-tooth timing belts can be grouped based on the distance (tooth pitch) between their material and their teeth. Double tooth timing belts are usually made of rubber. They can be pitched in inch sizes D-XL, D-L, D-H, D-XH (these are called classic timing belts), or they can be metric pitches D-3M, D-5M, D-8M, D-S8M, D-14M. We use timing belts made of polyurethane for certain applications. The most commonly used sizes are: D-T5, D-T10. The design of PU double-tooth timing belts differs from rubber designs, because in PU products the teeth are not located opposite each other on the two sides of the belt, but offset by the size of the pitch...

Timing belts are delivered from the manufacturers in 100-200 cm wide coils per size. The final width is cut at the time of the customer order. Due to the individual production of these types of belts, we do not accept cancellations from the customer after the confirmation has been sent. We do not exchange or return these products.

I'll check it out

Profile D-S8M lawn mower double-toothed toothed belt

I'll check it out

Profile D-S8M lawn mower double-toothed toothed belt

I'll check it out

Profil D-S8M double-sided timing belt

I'll check it out

Profil D-S8M double-sided timing belt

I'll check it out

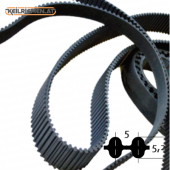

Profile D-HTD5M double-toothed toothed belt

I'll check it out

Profile D-HTD5M double-toothed toothed belt

I'll check it out

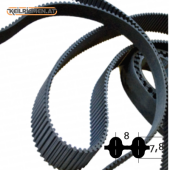

Profil D-HTD8M Curele dublu dintate

I'll check it out

Profil D-HTD8M Curele dublu dintate

I'll check it out

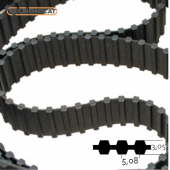

Profile D-HTD14M double-toothed toothed belt

I'll check it out

Profile D-HTD14M double-toothed toothed belt

I'll check it out

Profile D-T5 double-tooth toothed belt

I'll check it out

Profile D-T5 double-tooth toothed belt

I'll check it out

Profile D-T10 double-toothed toothed belt

I'll check it out

Profile D-T10 double-toothed toothed belt

I'll check it out

Profile D-XL double-toothed toothed belt

I'll check it out

Profile D-XL double-toothed toothed belt

I'll check it out

Profile D-L double-toothed toothed belt

I'll check it out

Profile D-L double-toothed toothed belt

I'll check it out

Profile D-H double-toothed toothed belt

I'll check it out

Profile D-H double-toothed toothed belt

Double-tooth timing belts can be grouped based on the distance (tooth pitch) between their material and their teeth. Double tooth timing belts are usually made of rubber. They can be pitched in inch sizes D-XL, D-L, D-H, D-XH (these are called classic timing belts), or they can be metric pitches D-3M, D-5M, D-8M, D-S8M, D-14M. We use timing belts made of polyurethane for certain applications. The most commonly used sizes are: D-T5, D-T10. The design of PU double-tooth timing belts differs from rubber designs, because in PU products the teeth are not located opposite each other on the two sides of the belt, but offset by the size of the pitch...

Timing belts are delivered from the manufacturers in 100-200 cm wide coils per size. The final width is cut at the time of the customer order. Due to the individual production of these types of belts, we do not accept cancellations from the customer after the confirmation has been sent. We do not exchange or return these products.

News

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next