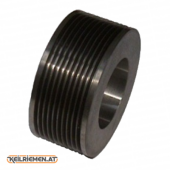

V-belt pulley

General information

A V-belt pulley is a mechanical component with a V-shaped groove (groove) that houses and drives a V-belt and transmits power between the pulley and the belt. The V-belt cannot be used without a V-belt pulley. The V-belt is tensioned in the trapezoidal groove milled into the pulley, so that the force load on the shaft does not increase significantly, even with higher normal forces. V-belts can be manufactured using various fastening methods. The most common is the simple pre-drilled V-belt pulley. This product requires machining.

General information

A V-belt pulley is a mechanical component with a V-shaped groove (groove) that houses and drives a V-belt and transmits power between the pulley and the belt. The V-belt cannot be used without a V-belt pulley. The V-belt is tensioned in the trapezoidal groove milled into the pulley, so that the force load on the shaft does not increase significantly, even with higher normal forces. V-belts can be manufactured using various fastening methods. The most common is the simple pre-drilled V-belt pulley. This product requires machining.

Also very common are V-belt pulleys for tension bushings, which do not require machining, since the tension bushing that fits into the pulley can be selected a version with a hole suitable for all types of shafts.

If you are looking for a V-belt pulley with a different fastening system, please contact us using our contact details or via the contact page.

Flat belt pulleys, timing belt pulleys, V-ribbed belt pulleys (Poly-V) are specially designed to accommodate flat, toothed and V-ribbed belts according to their type (appropriate markings). It is not recommended to use flat, ribbed and timing belts on other types of pulleys as this can lead to a drastic reduction in service life!

The timing belt pulley is the drive element of the timing belt. Its teeth are specially tailored to the pitch and profile of different timing belts. They are usually made of steel or aluminum, but very large examples can also be made of cast iron. There are versions with and without a border, and a separate border is also available. They are made in fixed widths, but discs with individual widths can also be made from splined shafts. The flat belt pulley is suitable for driving flat belts of different profile heights. What they have in common is the barrel construction, which is responsible for the tension of the belt. They are usually made of cast iron. There is also a version with and without a border. They are manufactured in fixed widths. The Poly-V pulley drives the V-ribbed belt. The advantage is that they can transmit a large torque even with a small diameter. The ribs on the pulley correspond exactly to the corresponding belt profile and are not interchangeable. They contain a fixed number of ribs, a belt narrower than the number of ribs of the pulley can be used on it, a wider belt, i.e. h. with more ribs, but cannot be used on the pulley with the specified rib.

Also very common are V-belt pulleys for tension bushings, which do not require machining, since the tension bushing that fits into the pulley can be selected a version with a hole suitable for all types of shafts.

If you are looking for a V-belt pulley with a different fastening system, please contact us using our contact details or via the contact page.

Flat belt pulleys, timing belt pulleys, V-ribbed belt pulleys (Poly-V) are specially designed to accommodate flat, toothed and V-ribbed belts according to their type (appropriate markings). It is not recommended to use flat, ribbed and timing belts on other types of pulleys as this can lead to a drastic reduction in service life!

The timing belt pulley is the drive element of the timing belt. Its teeth are specially tailored to the pitch and profile of different timing belts. They are usually made of steel or aluminum, but very large examples can also be made of cast iron. There are versions with and without a border, and a separate border is also available. They are made in fixed widths, but discs with individual widths can also be made from splined shafts. The flat belt pulley is suitable for driving flat belts of different profile heights. What they have in common is the barrel construction, which is responsible for the tension of the belt. They are usually made of cast iron. There is also a version with and without a border. They are manufactured in fixed widths. The Poly-V pulley drives the V-ribbed belt. The advantage is that they can transmit a large torque even with a small diameter. The ribs on the pulley correspond exactly to the corresponding belt profile and are not interchangeable. They contain a fixed number of ribs, a belt narrower than the number of ribs of the pulley can be used on it, a wider belt, i.e. h. with more ribs, but cannot be used on the pulley with the specified rib.

News

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next