Hub sprockets

General information

In addition to roller chains, sprockets are indispensable accessories for chain drives. A chain drive shall consist of at least one chain and at least two sprockets. Sprockets are always selected for the roller chain to be used. The division of the Sprocket must be perfectly consistent with the division of the roller chain. The width of the sprocket must fit within the minimum internal width of the roller chain. The roller diameter of the roller rampart must correspond to the curves formed in the grooves of the sprocket.

General information

In addition to roller chains, sprockets are indispensable accessories for chain drives. A chain drive shall consist of at least one chain and at least two sprockets. Sprockets are always selected for the roller chain to be used. The division of the Sprocket must be perfectly consistent with the division of the roller chain. The width of the sprocket must fit within the minimum internal width of the roller chain. The roller diameter of the roller rampart must correspond to the curves formed in the grooves of the sprocket.

For simplicity, always use a sprocket marked with the same marking as your roller chain. Due to the design of the roller chain, chains marked 083 and 084 require a completely identical sprocket, this is available in group 083. Hub sprockets contain a wider part called a hub on ONE side of their axle (shape B). By machining the hub, we can create different forms of connection and attachment. The most commonly designed hub section has a hole and a latch track, but screw fastening, ribbed shaft nests, or even seeger ring fastenings are also common. The hub is delivered unmachined (with a base hole), machining is the responsibility of the customer.

If you do not want to engage in machining, use a tapered clamping sprocket instead of a hub sprocket. If the installation warrants it, we can use a sprocket instead of a hub sprocket.

I'll check it out

04B hub sprockets

I'll check it out

04B hub sprockets

I'll check it out

05B hub sprockets

I'll check it out

05B hub sprockets

I'll check it out

06B hub sprockets

I'll check it out

06B hub sprockets

I'll check it out

081 hub sprockets

I'll check it out

081 hub sprockets

I'll check it out

083 hub sprockets

I'll check it out

083 hub sprockets

I'll check it out

085 hub sprockets

I'll check it out

085 hub sprockets

I'll check it out

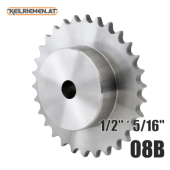

08B hub sprockets

I'll check it out

08B hub sprockets

I'll check it out

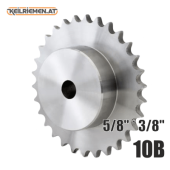

10B hub sprockets

I'll check it out

10B hub sprockets

I'll check it out

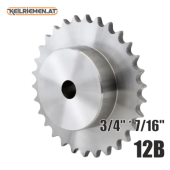

12B hub sprockets

I'll check it out

12B hub sprockets

I'll check it out

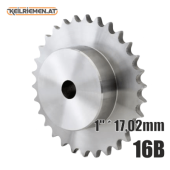

16B hub sprockets

I'll check it out

16B hub sprockets

I'll check it out

20B hub sprockets

I'll check it out

20B hub sprockets

I'll check it out

24B hub sprockets

I'll check it out

24B hub sprockets

I'll check it out

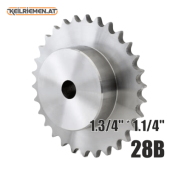

28B hub sprockets

I'll check it out

28B hub sprockets

I'll check it out

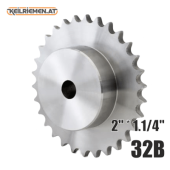

32B hub sprockets

I'll check it out

32B hub sprockets

I'll check it out

06A hub sprockets

I'll check it out

06A hub sprockets

I'll check it out

08A hub sprockets

I'll check it out

08A hub sprockets

I'll check it out

12A hub sprockets

I'll check it out

12A hub sprockets

I'll check it out

16A hub sprockets

I'll check it out

16A hub sprockets

I'll check it out

20A hub sprockets

I'll check it out

20A hub sprockets

I'll check it out

24A hub sprockets

I'll check it out

24A hub sprockets

For simplicity, always use a sprocket marked with the same marking as your roller chain. Due to the design of the roller chain, chains marked 083 and 084 require a completely identical sprocket, this is available in group 083. Hub sprockets contain a wider part called a hub on ONE side of their axle (shape B). By machining the hub, we can create different forms of connection and attachment. The most commonly designed hub section has a hole and a latch track, but screw fastening, ribbed shaft nests, or even seeger ring fastenings are also common. The hub is delivered unmachined (with a base hole), machining is the responsibility of the customer.

If you do not want to engage in machining, use a tapered clamping sprocket instead of a hub sprocket. If the installation warrants it, we can use a sprocket instead of a hub sprocket.

News

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next