Conical clamping sprockets

General information

In addition to roller chains, sprockets are indispensable accessories for chain drives. A chain drive shall consist of at least one chain and at least two sprockets. Sprockets are always selected for the roller chain to be used. The division of the sprocket must perfectly match the division of the roller chain. The width of the sprocket must fit within the minimum internal width of the roller chain. The roller diameter of the roller rampart must correspond to the curves formed in the grooves of the sprocket. For simplicity, always use a sprocket marked with the same marking as your roller chain.

General information

In addition to roller chains, sprockets are indispensable accessories for chain drives. A chain drive shall consist of at least one chain and at least two sprockets. Sprockets are always selected for the roller chain to be used. The division of the sprocket must perfectly match the division of the roller chain. The width of the sprocket must fit within the minimum internal width of the roller chain. The roller diameter of the roller rampart must correspond to the curves formed in the grooves of the sprocket. For simplicity, always use a sprocket marked with the same marking as your roller chain.

Due to the design of the roller chain, chains marked 083 and 084 require a completely identical sprocket.

Conical clamping sprockets are specially designed hub sprockets where the socket of the associated tapered clamping has already been worked into the hub. The advantage of tapered clamping sprockets is that by pairing the sprocket with the matching tapered clamp we get an immediately usable drive technology element, no subsequent machining is required. The tapered clamp is not included with the sprocket, it must be purchased separately here. The part number of each sprocket shall include the corresponding clamp number.

If you want to mount a tapered clamping sprocket on an axle that is too large for its diameter, you will not find a tapered clamp with a suitable hole. In such cases, a basic drilled sprocket (hub or flat design) must be chosen and machined to the desired hole size!

I'll check it out

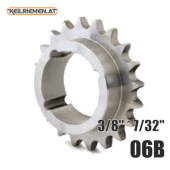

06B tapered clamping sprockets

I'll check it out

06B tapered clamping sprockets

I'll check it out

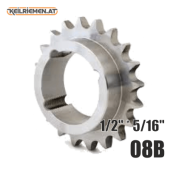

08B tapered clamping sprockets

I'll check it out

08B tapered clamping sprockets

I'll check it out

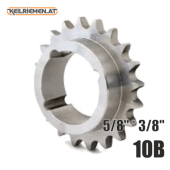

10B tapered clamping sprockets

I'll check it out

10B tapered clamping sprockets

I'll check it out

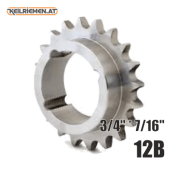

12B tapered clamping sprockets

I'll check it out

12B tapered clamping sprockets

I'll check it out

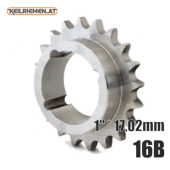

16B tapered clamping sprockets

I'll check it out

16B tapered clamping sprockets

I'll check it out

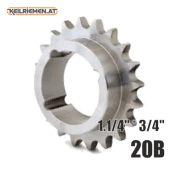

20B tapered clamping sprockets

I'll check it out

20B tapered clamping sprockets

I'll check it out

24B tapered clamping sprockets

I'll check it out

24B tapered clamping sprockets

Due to the design of the roller chain, chains marked 083 and 084 require a completely identical sprocket.

Conical clamping sprockets are specially designed hub sprockets where the socket of the associated tapered clamping has already been worked into the hub. The advantage of tapered clamping sprockets is that by pairing the sprocket with the matching tapered clamp we get an immediately usable drive technology element, no subsequent machining is required. The tapered clamp is not included with the sprocket, it must be purchased separately here. The part number of each sprocket shall include the corresponding clamp number.

If you want to mount a tapered clamping sprocket on an axle that is too large for its diameter, you will not find a tapered clamp with a suitable hole. In such cases, a basic drilled sprocket (hub or flat design) must be chosen and machined to the desired hole size!

News

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next