ISO roller chains

General information

A significant part of the roller chains used in Europe are manufactured according to ISO R606. This standard is originally based on the English standard BS228, which is why ISO chains are often referred to as ISO (BS) roller chains. Based on their structure, roller chains consist of a pin, roller, connecting plate (sponge cake). The material and design of the parts determine the quality of the roller chains. However, the value specified in the standard is usually met by any roller chain. In everyday use, reinforced chains are usually not required. The ISO (BS) standard does not specify a standard for reinforced designs.

General information

A significant part of the roller chains used in Europe are manufactured according to ISO R606. This standard is originally based on the English standard BS228, which is why ISO chains are often referred to as ISO (BS) roller chains. Based on their structure, roller chains consist of a pin, roller, connecting plate (sponge cake). The material and design of the parts determine the quality of the roller chains. However, the value specified in the standard is usually met by any roller chain. In everyday use, reinforced chains are usually not required. The ISO (BS) standard does not specify a standard for reinforced designs.

Reinforced ISO roller chains made by each manufacturer are manufactured according to the individual ideas of the manufacturers. (From reinforced chains, ANSI H variants are also widespread in Europe.)

When using chain drives, the tensile strength of the roller chains specified in the catalogue must always be taken into account!

How to recognize ISO BS roller chains?

A power chain can generally be characterized by three parameters. The first is the pin spacing, which is also called simply division. This means the distance at which the links in the chain rotate over each other. This determines how large a sprocket can be used. The second important information is the roller diameter. This is the outer diameter of the cylinder pulled on the pin. This surface touches the arch formed at the base of the teeth of the sprocket. And the third important feature is the inner width. This is measured between the two links (sponge cakes) of the chain in the narrowest part. This size determines the width of the chain sprocket. Of course, in addition to the above dimensions, a thousand other things can be measured on a chain, and a thousand other things can be important for a specific application. However, knowing the division, roller diameter and inner width, it is already possible to identify a roller chain.

Why do we speak in inches when we call ISO chains European roller chains?

In essence, it is because of the English origin of the roller chain standard that ISO standard chains are dimensioned based on inch sizes. The smallest (and most recently created) graduation roller chains are divided by 03B, 04B and 05B metric. The division of all other ISO roller chains from 06B to 64B can always be expressed in inch size. For simpler interpretation, inch sizes are also designated as metric decimals. (for example: 3/8=9.525mm, 1/2=12.7mm, 5/8=15.875mm and so on) Further technical data for the products can be found in the catalogues under the Downloadable Documents tab!

How are ISO BS chains marked, what does the numbering of ISO BS chains mean?

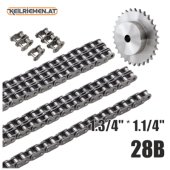

BS stands for British Standard. The letter B after the identification number also indicates this. The marking itself can be traced back to the inch size. The number of ISO roller chains is always 1/16th of the inch size. (1 inch = 25.4mm.) The chain marked 06B has a division of 6/16th, or 3/8 inch. The division of the chain marked 08B is 8/16, i.e. 1/2 inch. The division of the bar marked 10B is 10/16th, or 5/8 inch. The chain marked 12B has a division of 12/16, that is, 3/4 inch. The chain marked 16B is divided by 16/16, i.e. 1 inch. The chain marked 20B is divided by 20/16, i.e. 1.25 inches. A24B has a chain division of 24/16, i.e. 1.5 inches. The roller chains marked 28B have a division of 28/16, i.e. 1.75 inches. The roller chains marked 32B have a division of 32/16, i.e. 2 inches. The roller chains marked 40B have a division of 40/16, i.e. 2.5 inches. The division of chains marked 48B is 48/16, i.e. 3 inches. The letter B at the end of the numbers refers to the British Standard.

I'll check it out

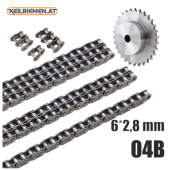

04B (6x2,8mm)

I'll check it out

04B (6x2,8mm)

I'll check it out

05B (8x3mm)

I'll check it out

05B (8x3mm)

I'll check it out

06B (9,5x5,7mm)

I'll check it out

06B (9,5x5,7mm)

I'll check it out

081 (12,7x3,3mm)

I'll check it out

081 (12,7x3,3mm)

I'll check it out

083 (12,7x4,9mm)

I'll check it out

083 (12,7x4,9mm)

I'll check it out

084 (12,7x4,9mm)

I'll check it out

084 (12,7x4,9mm)

I'll check it out

085 (12,7x6,3mm)

I'll check it out

085 (12,7x6,3mm)

I'll check it out

08B (12,7x7,8mm)

I'll check it out

08B (12,7x7,8mm)

I'll check it out

10B (15,9x9,7mm)

I'll check it out

10B (15,9x9,7mm)

I'll check it out

12B (19,1x11,7mm)

I'll check it out

12B (19,1x11,7mm)

I'll check it out

16B (25,4x17mm)

I'll check it out

16B (25,4x17mm)

I'll check it out

20B (31,8x19,6mm)

I'll check it out

20B (31,8x19,6mm)

I'll check it out

24B (38,1x25,4mm)

I'll check it out

24B (38,1x25,4mm)

I'll check it out

28B (44,5x31mm)

I'll check it out

28B (44,5x31mm)

I'll check it out

32B (50,8x31mm)

I'll check it out

32B (50,8x31mm)

I'll check it out

40B (63,5x38,1mm)

I'll check it out

40B (63,5x38,1mm)

I'll check it out

48B (76,2x45,7mm)

I'll check it out

48B (76,2x45,7mm)

Reinforced ISO roller chains made by each manufacturer are manufactured according to the individual ideas of the manufacturers. (From reinforced chains, ANSI H variants are also widespread in Europe.)

When using chain drives, the tensile strength of the roller chains specified in the catalogue must always be taken into account!

How to recognize ISO BS roller chains?

A power chain can generally be characterized by three parameters. The first is the pin spacing, which is also called simply division. This means the distance at which the links in the chain rotate over each other. This determines how large a sprocket can be used. The second important information is the roller diameter. This is the outer diameter of the cylinder pulled on the pin. This surface touches the arch formed at the base of the teeth of the sprocket. And the third important feature is the inner width. This is measured between the two links (sponge cakes) of the chain in the narrowest part. This size determines the width of the chain sprocket. Of course, in addition to the above dimensions, a thousand other things can be measured on a chain, and a thousand other things can be important for a specific application. However, knowing the division, roller diameter and inner width, it is already possible to identify a roller chain.

Why do we speak in inches when we call ISO chains European roller chains?

In essence, it is because of the English origin of the roller chain standard that ISO standard chains are dimensioned based on inch sizes. The smallest (and most recently created) graduation roller chains are divided by 03B, 04B and 05B metric. The division of all other ISO roller chains from 06B to 64B can always be expressed in inch size. For simpler interpretation, inch sizes are also designated as metric decimals. (for example: 3/8=9.525mm, 1/2=12.7mm, 5/8=15.875mm and so on) Further technical data for the products can be found in the catalogues under the Downloadable Documents tab!

How are ISO BS chains marked, what does the numbering of ISO BS chains mean?

BS stands for British Standard. The letter B after the identification number also indicates this. The marking itself can be traced back to the inch size. The number of ISO roller chains is always 1/16th of the inch size. (1 inch = 25.4mm.) The chain marked 06B has a division of 6/16th, or 3/8 inch. The division of the chain marked 08B is 8/16, i.e. 1/2 inch. The division of the bar marked 10B is 10/16th, or 5/8 inch. The chain marked 12B has a division of 12/16, that is, 3/4 inch. The chain marked 16B is divided by 16/16, i.e. 1 inch. The chain marked 20B is divided by 20/16, i.e. 1.25 inches. A24B has a chain division of 24/16, i.e. 1.5 inches. The roller chains marked 28B have a division of 28/16, i.e. 1.75 inches. The roller chains marked 32B have a division of 32/16, i.e. 2 inches. The roller chains marked 40B have a division of 40/16, i.e. 2.5 inches. The division of chains marked 48B is 48/16, i.e. 3 inches. The letter B at the end of the numbers refers to the British Standard.

News

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next

„Zwei bezahlen – drei erhalten“-Aktion für Einzelpersonen

Vom 6. Dezember 2025 bis zum 31. Dezember 2025 nehmen alle Bestellungen von Antriebsriemen durch registrierte Personen an unserer Aktion „Zwei kaufen – drei erhalten“ teil!***

next