Automotive V-belts

General information

Automotive belts are very similar to toothed V-belts with a narrow profile. They are identical in most of their parameters and have similar mechanical applications. They can withstand high-speed drive and small-scale disc pass-through. They are well resistant to oils and resistant to vibrations. They can typically be used between -25 and +100 °C. Versions made of EPDM material allow applications from -45 to +120 °C. Some of their dimensions have a different "trapezoid" serration than other serrated belts. They typically have little elongation and tolerate strain well.

General information

Automotive belts are very similar to toothed V-belts with a narrow profile. They are identical in most of their parameters and have similar mechanical applications. They can withstand high-speed drive and small-scale disc pass-through. They are well resistant to oils and resistant to vibrations. They can typically be used between -25 and +100 °C. Versions made of EPDM material allow applications from -45 to +120 °C. Some of their dimensions have a different "trapezoid" serration than other serrated belts. They typically have little elongation and tolerate strain well.

Their advantage is that they come in a large number of sizes (close to each other), so they are often used for industrial or agricultural applications in machines where the wheelbase cannot be adjusted. (Because there are sizes that other straps don't.)

We often use automotive belts to replace V-belts of other profiles that are not currently available. Almost all smaller classic or narrow profile V-belts can be switched to automotive belts, as there is a particularly large selection of automotive belts. When switching to an automotive belt, the profile width of the original belt must be taken into account, in case of length size the outer size of the original belt must be calculated and the corresponding automotive belt must be selected. However, we do not recommend replacing a narrow-profile toothed V-belt with an automotive belt in places of use where high tension forces are generated, where the drive is impulsive, where there are multi-track systems, or where replacement is prohibited by the manual.

I'll check it out

10x8 (AVX10) automotive V-belt

I'll check it out

10x8 (AVX10) automotive V-belt

I'll check it out

Banded AVX10 (HAVX10) Automotive V-Belt

I'll check it out

Banded AVX10 (HAVX10) Automotive V-Belt

I'll check it out

11.5x8 (AVX11) automotive V-belt

I'll check it out

11.5x8 (AVX11) automotive V-belt

I'll check it out

13x10 (AVX13) automotive V-belt

I'll check it out

13x10 (AVX13) automotive V-belt

I'll check it out

Banded AVX13 (HAVX13) Automotive V-belt

I'll check it out

Banded AVX13 (HAVX13) Automotive V-belt

I'll check it out

17x11 (AVX17) automotive V-belt

I'll check it out

17x11 (AVX17) automotive V-belt

Their advantage is that they come in a large number of sizes (close to each other), so they are often used for industrial or agricultural applications in machines where the wheelbase cannot be adjusted. (Because there are sizes that other straps don't.)

We often use automotive belts to replace V-belts of other profiles that are not currently available. Almost all smaller classic or narrow profile V-belts can be switched to automotive belts, as there is a particularly large selection of automotive belts. When switching to an automotive belt, the profile width of the original belt must be taken into account, in case of length size the outer size of the original belt must be calculated and the corresponding automotive belt must be selected. However, we do not recommend replacing a narrow-profile toothed V-belt with an automotive belt in places of use where high tension forces are generated, where the drive is impulsive, where there are multi-track systems, or where replacement is prohibited by the manual.

News

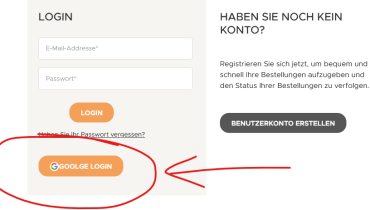

Melden Sie sich mit einem GOOGLE-Konto im keilriemen.at Webshop an!

Ab dem 23.02.2026 ist die Anmeldung mit Google im keilriemen.at Webshop möglich!

next

Melden Sie sich mit einem GOOGLE-Konto im keilriemen.at Webshop an!

Ab dem 23.02.2026 ist die Anmeldung mit Google im keilriemen.at Webshop möglich!

next

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Hallo 2026, wir kommen!

Der reguläre Betrieb im Webshop keilriemen.at beginnt am 5. Januar 2026! Allgemeine Informationen zur Bestellabwicklung finden Sie im Artikel.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Feiertagsöffnungszeiten

Der Online-Shop keilriemen.at ist während der Feiertage durchgehend erreichbar, wir nehmen auch Bestellungen entgegen. Allerdings werden Paketversand und Kundenservice zwischen dem 22. Dezember 2025 und dem 5. Januar 2026 um 8 Uhr morgens eingestellt.

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next

Weihnachtslieferfristen

Da die Feiertage zum Jahresende näher rücken, beachten Sie bitte die folgenden Fristen, wenn Sie Ihre Bestellung noch vor Weihnachten erhalten möchten!

next